Specializing Customized Tubular Electric Heat Pipe Production Cast Aluminum Water Heating element

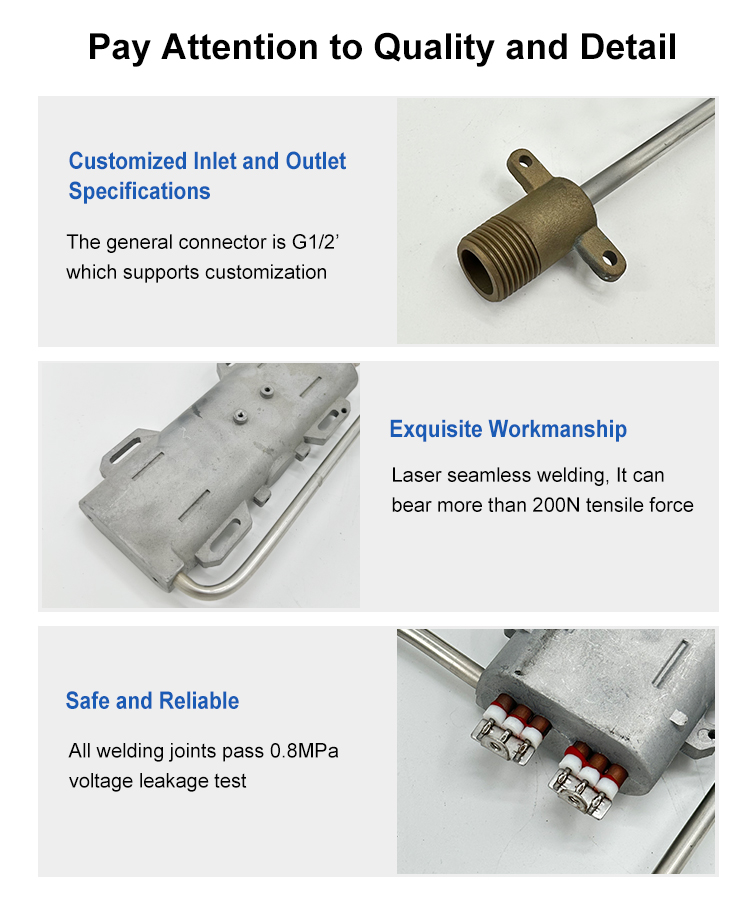

1.Superior Heat Distribution 30% faster thermal conductivity vs. steel elements,Saves 18% energy vs. traditional coil heaters High thermal efficiency rating, Even heat spread eliminates cold spots (±2°C variance). 2.High Grade Durability Corrosion-resistant alloy survives 5000+ salt spray test hours pH 3-12 chemical environments 3.Customization Capabilities A. Tailored Power Solutions • Voltage: 100V-400V (Residential/Industrial) • Power: 1KW-20KW Scalable Output • Phase Options: Single/Three-Phase Support B. Design Flexibility • Shapes: U/Tube/Plate/Serpentine • Surface Finishes: Anodized/Powder-Coated/Polished • Mounting: Flange/Bracket/Threaded Ends

At our ISO 9001-certified facility, every cast aluminum heating element undergoes precision engineering from raw material to final product. New high-grade aluminum alloys are melted at 720°C±5°C in vacuum die-casting chambers, achieving pore-free structures with ≤0.2% porosity. Post-casting, CNC machining ensures ±0.05mm dimensional accuracy, by triple-stage thermal aging tests (-30°C to 450°C cycling) to guarantee structural integrity.

100% of units pass our 12-point safety validation protocol, including 5000V Hi-POT insulation checks, <0.5mA leakage current compliance (exceeding IEC 60335-2), and IP waterproof validation. Each batch undergoes 72-hour continuous load testing at 120% rated power, with real-time thermal imaging verifying uniform heat distribution (±2°C variance).

Established in 2006,Zhongshan Chongde Electric Co.,Ltd

As a high-tech company, we have advanced technology and experienced R&D talent team .The main products include: electric instant water heaters, heating element, faucets and related accessories, etc. The products have ETL CE CB Rohs FCC CCC TUV SGS certification.

Scan to wechat